Core Functions and Mechanical Advantages of Rubber Washers

Definition and Primary Function of Rubber Washers in Mechanical Systems

Rubber washers come in disc shapes and act as seals that keep mechanical systems working properly. These flexible parts do several important things at once they stop leaks by getting compressed, soak up vibrations from machinery movement, and spread out the pressure when bolts or screws are tightened between two surfaces. What makes them stand out compared to hard plastic or metal options is how they adapt to uneven surfaces without losing their grip. Even when pressure builds up to around 2,500 pounds per square inch, these rubber seals still manage to maintain about 95% effectiveness according to recent findings published in Material Engineering Reports back in 2023. This kind of performance matters a lot in industrial settings where small leaks can cause big problems over time.

Flexibility, Compressibility, and Resilience Under Dynamic Loads

Rubber washers can compress up to 40% without permanent deformation and maintain 92% resilience across extreme temperatures (-40°C to 150°C). This flexibility ensures reliable performance in high-vibration environments such as engine mounts, where industry studies show a 30% reduction in bolt loosening incidents compared to metal washers.

Common Types: Flat Washers, O-rings, and Bonded Rubber Washers

- Flat washers: Provide basic load distribution under bolts and nuts

- O-rings: Serve as circular seals in hydraulic and pneumatic systems

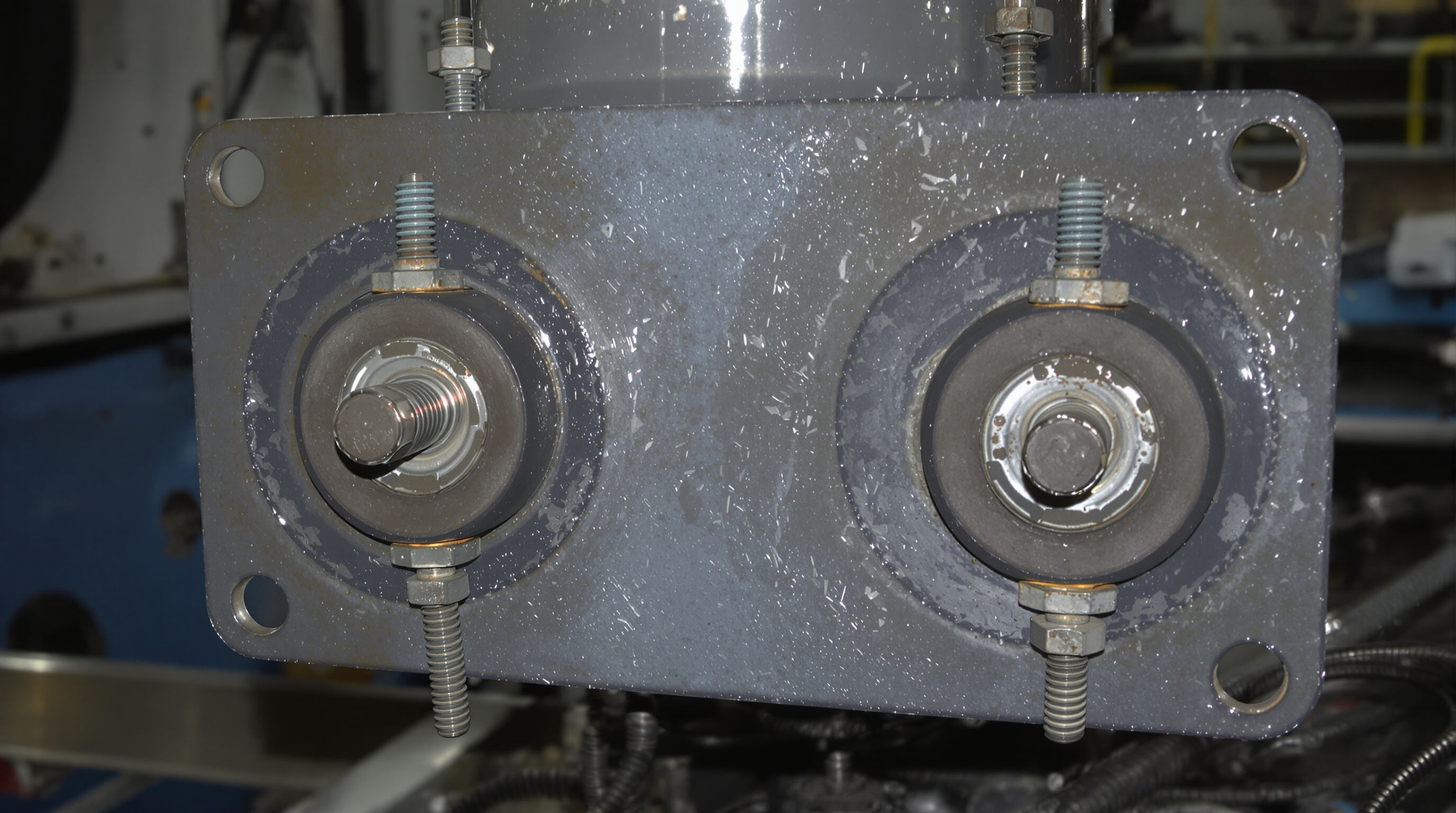

- Bonded variants: Combine rubber with metal substrates for high-stress industrial joints

In turbocharger applications, bonded rubber washers extend gasket lifespan by 60% due to enhanced thermal and mechanical resistance, according to automotive manufacturers.

Sealing Performance and Leak Prevention in Dynamic Joints

Role of Rubber Washers in Sealing Joints Under Vibration and Pressure

Rubber washers maintain fluid-tight seals by conforming to microscopic surface imperfections between mating parts. Their viscoelastic nature enables consistent performance under pressures up to 2,500 PSI and vibration frequencies exceeding 120 Hz. A 2023 study published in Chemical Engineering Transactions found nitrile rubber washers reduced leakage rates by 92% compared to metal-only seals in pump assemblies, underscoring their importance in dynamic industrial settings.

Case Study: Hydraulic System Failure Due to Inadequate Rubber Washer Sealing

A mining operation incurred $480,000 in downtime after hydraulic cylinders failed within six months of installation. Post-failure analysis revealed that standard EPDM washers degraded under cyclical 1,800 PSI loads, allowing fluid leaks that contaminated servo valves. Switching to fluorocarbon (FKM) washers—offering 40% higher compression resistance—resulted in over 18 months of leak-free operation, demonstrating the critical impact of material compatibility on reliability.

Emerging Trend: Smart Sealing Materials Enhancing Traditional Rubber Washers

Manufacturers are now embedding microsensors into rubber washers to enable real-time monitoring of seal integrity. These smart components detect pressure drops of ≤15% and temperature spikes above 300°F, supporting predictive maintenance strategies. Early adopters in aerospace report a 30% reduction in unplanned seal replacements, though higher costs currently limit broad adoption in general industrial applications.

Vibration Dampening and Noise Reduction in Industrial Applications

Mechanisms of Vibration Absorption and Acoustic Insulation

Rubber washers work to soak up mechanical vibrations because they turn kinetic energy into heat through internal friction. This happens naturally due to how rubber behaves when it's both elastic and viscous at the same time. The fact that rubber can be compressed helps it fit around surfaces that aren't perfectly aligned. Plus there are tiny air pockets inside the rubber material that get in the way of sound waves traveling through. When these two things happen together, equipment such as compressors and pumps experience lower resonant frequencies somewhere between 15 and maybe even 30 Hz below what they would normally be. Lower frequencies mean less wear and tear on structures over time and also creates a quieter operating environment overall.

Data Insight: 40% Noise Reduction in Industrial Pumps Using Nitrile Rubber Washers

In actual field testing, pumps equipped with nitrile rubber washers saw their operational noise drop dramatically from about 85 decibels down to just 51 decibels when running continuously. The material's damping properties range between 0.25 and 0.35, which gives it a clear edge over alternatives like neoprene and silicone when put through long stress tests. What makes nitrile stand out is how well it keeps seals intact while still absorbing vibrations effectively even after sitting under pressure for three straight days. Maintenance crews have reported something pretty significant too - systems that got upgraded to these nitrile washers required roughly 38 percent fewer maintenance checks across an 18 month period, according to plant operators who've been tracking performance metrics closely.

Best Practice: Strategic Placement for Optimal Shock and Resonance Mitigation

- Mounting Interfaces: Install between motor housings and frames to isolate 60–80% of axial vibrations

- Bolt Load Zones: Use bonded washers beneath fastener heads to resist loosening from lateral forces

- Piping Connections: Position near valve assemblies to mitigate fluid hammer effects

Aligning washers with natural vibration nodes increases effectiveness by up to 200%, while staggered configurations around rotating shafts provide 55% better resonance control than single-layer setups.

Load Distribution and Wear Protection in Bolted Connections

Equalizing Stress and Preventing Localized Wear in Fastened Joints

Rubber washers work by distributing pressure across a larger surface area, which helps stop those annoying spots of wear that happen when metal parts rub together directly on rough or mismatched surfaces. Studies from Tribology International show something pretty interesting about them actually reducing wear problems by around 60 to 70 percent in places where there's lots of vibration, much better than regular joints without any cushioning. What makes these washers so good at what they do is their ability to flex and fill in gaps between imperfect surfaces. This keeps things running smoothly even when forces are constantly changing direction or intensity, making them really valuable components in many mechanical applications.

| Application | Without Washers | With Rubber Washers |

|---|---|---|

| Surface Deformation | 0.12 mm | 0.03 mm |

| Bolt Loosening Rate | 18% per 1k hours | 4% per 1k hours |

Case Study: Extended Service Life of Mining Equipment With Rubber Washers

A 2023 field study on heavy-duty mining conveyors showed neoprene rubber washers increased bolt joint lifespan by 300%. Previously, pivot joints suffered fastener failure every 6–8 weeks due to abrasive dust ingress and cyclic stress. After retrofitting with bonded rubber washers, operators achieved:

- 82% reduction in joint replacement frequency

- 41% lower maintenance costs per operational hour

- Elimination of unplanned downtime from joint failures

These results support emerging best practices in industrial bolting, where elastomeric interfaces are increasingly adopted for machinery exposed to particulate contamination and shock loads.

Material Selection for Durability, Chemical Resistance, and Sustainability

Comparing Nitrile, EPDM, Silicone, and Viton for Industrial Environments

Nitrile rubber stands out for its great resistance to oils and works well across a pretty wide temperature range, from as cold as -40 degrees Celsius all the way up to 108 degrees. That makes it a go to material for things like fuel lines and lubrication systems where reliability matters most. Then there's EPDM which handles steam, water, and even ozone quite nicely. We often see this type used outdoors or in those big HVAC systems because it holds up so well against weathering over time. Silicone takes things further when it comes to flexibility under extreme conditions. It can handle temperatures ranging between -60 and 232 degrees Celsius, which explains why manufacturers rely on it heavily in both aerospace components and automotive parts that need to withstand harsh environments. Viton or FKM as it's technically known has amazing resistance against various chemicals including fuels, acids, and solvents. However, one downside is that it doesn't stretch as much when temperatures drop below freezing point compared to other materials.

Silicone vs. Viton: Trade-offs in High-Temperature Applications

Silicone works well in exhaust systems up until about 200 degrees Celsius where it stays flexible, though it starts breaking down once it comes into contact with hydrocarbons. On the other hand, Viton seals hold up pretty good in places where there's lots of oil around even at 150°C temperatures, but get really stiff and crack easily if they drop below minus 20°C. According to research published last year by some folks studying plastics under extreme conditions, Viton actually lasts roughly two and a half times longer than silicone does in those refinery pump connections. That kind of difference makes all the sense in the world when picking materials for specific applications based on what actual operating conditions will be like day after day.

Future Direction: Bio-Based Rubber Alternatives in Sustainable Manufacturing

Bio-polyurethane washers now achieve 85% fossil fuel displacement while retaining 91% of traditional tensile strength (32 MPa vs. 35 MPa). Leading producers are integrating algae-derived elastomers, reducing carbon emissions by 64% per lifecycle assessment data from the Circular Materials Institute (2024).

Strategy: Aligning Rubber Washer Material with Operational Demands

Effective selection requires mapping chemical exposure, thermal cycling, and mechanical stress. For wastewater treatment, EPDM’s chlorine resistance surpasses nitrile; for solar panel mounts, silicone’s UV stability is optimal. Always reference ASTM D395 compression set values alongside expected load cycles to ensure long-term performance.

FAQ

What are the primary functions of rubber washers in mechanical systems?

Rubber washers act as seals, prevent leaks, absorb vibrations, and distribute pressure in mechanical systems.

How do rubber washers reduce noise in industrial applications?

Rubber washers dampen vibrations by converting kinetic energy into heat, which reduces operational noise levels significantly.

What are some common types of rubber washers?

Common types include flat washers, O-rings, and bonded rubber washers, each serving distinct functions in different applications.

How do embedded microsensors benefit rubber washers?

Embedded microsensors provide real-time monitoring, detecting pressure drops and temperature spikes, aiding in predictive maintenance.

Table of Contents

- Core Functions and Mechanical Advantages of Rubber Washers

- Sealing Performance and Leak Prevention in Dynamic Joints

- Vibration Dampening and Noise Reduction in Industrial Applications

- Load Distribution and Wear Protection in Bolted Connections

- Material Selection for Durability, Chemical Resistance, and Sustainability

- FAQ