Selecting the Right O-Ring Material for High-Temperature and High-Pressure Applications

Matching Elastomers to Extreme Conditions: Viton® (FKM), Nitrile, Silicone, and PTFE

Choosing the right materials makes all the difference when working in harsh conditions. Take fluorocarbon rubber, known commercially as Viton. This stuff can handle temps as high as 400 degrees Fahrenheit before breaking down, plus it stands up pretty well against oils and fuels too. That's why so many aerospace engineers turn to it for hydraulic systems, especially when referencing temperature charts for o-ring materials. When things get really cold though, silicone becomes the go to option since it stays flexible even at minus 65 degrees Fahrenheit or colder. Just keep in mind that while silicone works great in freezing conditions, it doesn't hold up as well against wear and tear compared to fluorocarbon rubber. Then there's PTFE which is fantastic at resisting chemicals, but manufacturers need to be extra careful with how they design glands because PTFE isn't very elastic. The lack of stretch means improper installation can lead to leaks or failures down the line.

Temperature Limits and Chemical Resistance Trade-Offs of O-Ring Materials

Every material involves compromises:

- Nitrile (NBR): Cost-effective with petroleum-based fluids but limited to 250°F (121°C)

- EPDM: Performs well in steam and water systems up to 300°F (149°C), yet degrades when exposed to hydrocarbons

- Aflas® (TFE/P): Offers stability at 450°F (232°C) with strong acid resistance, though vulnerable to ketones

Degradation Risks Under High-Pressure Gases: Oxidation, Hardening, and Hydrogen-Induced Swelling

At pressures exceeding 5,000 psi, hydrogen diffusion can swell FKM seals by 8-15% (2023 Polymer Degradation Study), creating leak paths. PTFE resists gas permeation but may cold-flow under sustained load. In hydrogen-rich environments, FFKM compounds with >90 Shore A hardness exhibit 40% lower swelling rates than standard FKM grades.

Key Selection Criteria Table

| Material | Max Temp (°F) | Chemical Strength | Pressure Limit (psi) |

|---|---|---|---|

| FKM | 400 | Oils, fuels, acids | 5,000 |

| Nitrile | 250 | Petroleum, water | 3,000 |

| Silicone | 450 | Water, ozone | 1,500 |

| PTFE | 500 | Strong acids, caustics | 10,000* |

*Requires anti-extrusion design

Understanding Temperature Effects on O-Ring Seal Integrity

Reversible vs. irreversible changes in elastomers at elevated temperatures

O-rings exposed to excessive heat undergo molecular changes that compromise sealing integrity. Reversible effects€”like temporary softening of silicone at 300°F (149°C)€”allow recovery after cooling. Irreversible degradation, such as Viton® (FKM) hardening at sustained 400°F (204°C), permanently reduces flexibility by 40-60% (SAE Aerospace Standards 2022). Studies show 63% of high-temperature O-ring failures result from oxidative cracking when thermal limits are exceeded.

Compression set and thermal expansion: Impact on long-term sealing performance

Thermal expansion causes O-rings to lose 15-30% of their initial compression force above 250°F (121°C), increasing leakage risk through uneven contact pressure. Nitrile (Buna-N) expands 0.3% volumetrically per 18°F (10°C) rise, while fluorosilicone maintains dimensional stability up to 350°F (177°C).

| Material | Thermal Expansion Coefficient (per °F) | Safe Continuous Temp Range |

|---|---|---|

| Silicone | 0.25% | -85°F to 450°F |

| EPDM | 0.18% | -40°F to 275°F |

| Perfluoroelastomer | 0.12% | -15°F to 600°F |

Data: ASTM D1418-21 (2023 update)

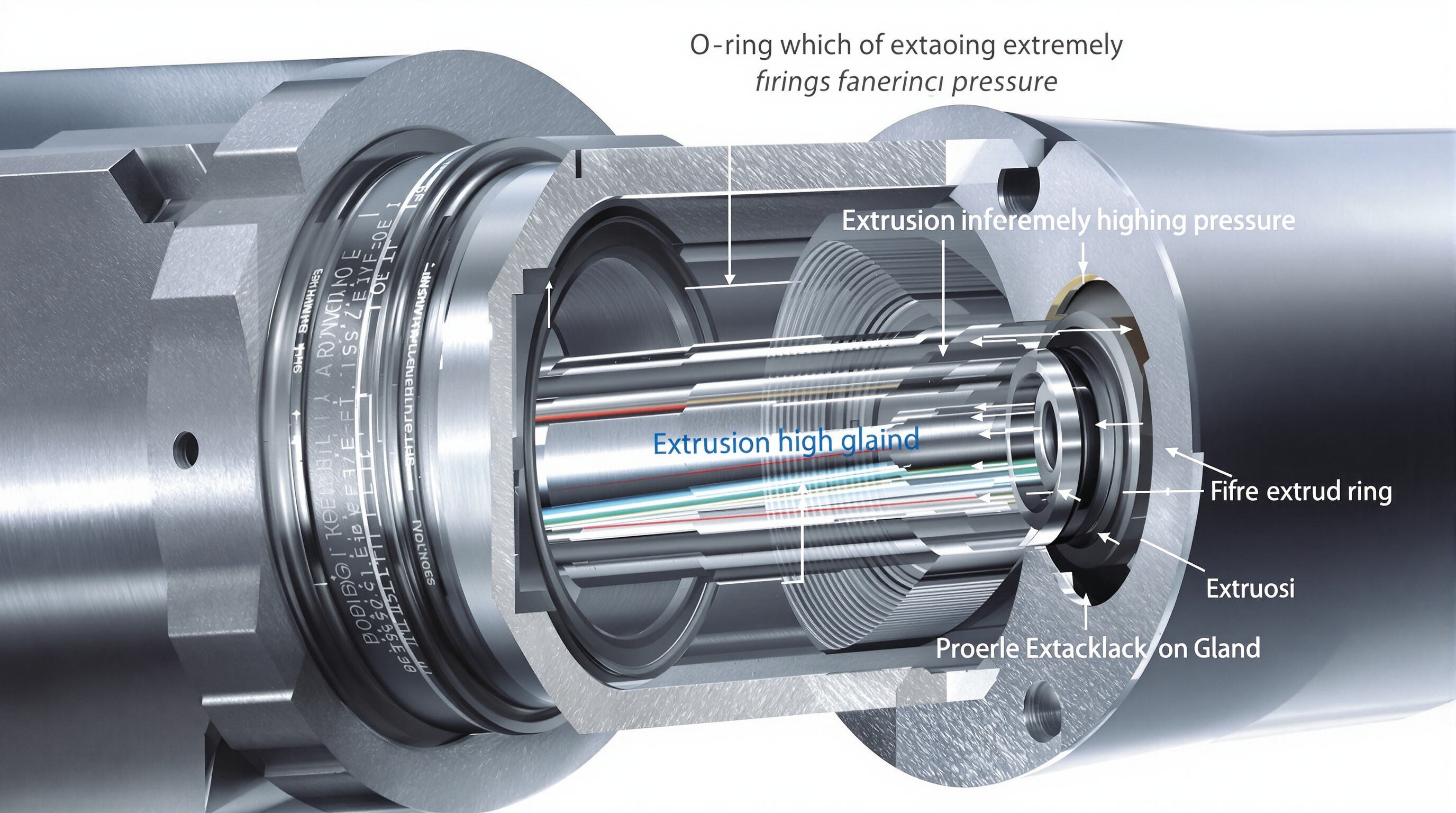

Managing High-Pressure Challenges: Extrusion, Stress, and Mechanical Failure

Stress Distribution and Load Limits in High-Pressure O-Ring Systems

In systems exceeding 5,000 psi, uneven stress distribution accelerates failure. Finite element analysis shows 70% of contact pressure concentrates on the seal€™s leading edge in static applications, increasing deformation risk. To mitigate this, engineers should:

- Choose materials matching compressive stress limits (e.g., HNBR for loads under 10,000 psi)

- Design glands with optimal radial squeeze (15-30% for dynamic seals) to balance sealing force and friction

Improperly rated O-rings fail 43% faster when subjected to pressure spikes beyond design thresholds.

Preventing Extrusion and Nibbling: Causes, Failures, and Design Considerations

Extrusion accounts for 62% of O-ring failures in hydraulic systems, typically due to:

- Clearance gaps over 0.005" relative to seal hardness

- Pressure surges bypassing anti-extrusion devices

- Dynamic motion causing "nibbling" at gland edges

Combining PTFE backup rings with optimized gland taper angles (15°-30°) reduces extrusion failures by 81% in 10,000-psi applications. Layered designs using metallic or thermoplastic anti-extrusion components allow 18-22% higher operating pressures compared to elastomer-only solutions.

Optimizing Gland Design and Mechanical Support for Reliable O-Ring Seals

Gland Geometry: Sizing, Tolerances, Groove Design, and Compression Optimization

For O-rings to work properly under high pressure conditions, getting the gland geometry right is absolutely essential. Most industry guidelines suggest around 15 to 30 percent radial compression for static seals, though the tolerances get really tight once pressures exceed 34 MPa or about 5,000 psi. The groove depth needs to account for thermal swelling too. Take FKM materials for instance they tend to expand between 3 and 7 percent when temperatures climb past 150 degrees Celsius. Keeping the groove fill ratio below 85 percent helps prevent extrusion issues while still leaving space for materials to expand when heated. This has been validated through various finite element analysis studies conducted across the industry.

Using Backup Rings to Prevent Extrusion in High-Pressure O-Ring Applications

At pressures over 69 MPa (10,000 psi), backup rings reduce extrusion risks by 62% (Parker Seal Group 2022). Made from PTFE or glass-reinforced nylon, they redistribute axial loads away from vulnerable elastomer zones. Best practices include:

- Matching backup ring thickness to O-ring cross-section (1:1 ratio)

- Using stepped or angled profiles in cyclic pressure applications

- Applying <20% compression to avoid overstressing

When properly implemented, these strategies extend seal life 3-5× in gas compression systems, where rapid pressure fluctuations cause most extrusion-related failures.

Testing, Validation, and Durability Assessment of O-Rings Under Extreme Conditions

Performance Testing: Compression Set, Burst Pressure, Leakage, and Rapid Gas Decompression Tests

Testing materials under extreme conditions helps ensure they'll hold up when things get tough in actual applications. For compression set evaluations, we look at how much shape a material retains after sitting in high heat for extended periods. Most important systems need something below 35% deformation to work properly. When it comes to burst pressure testing, engineers want to know exactly what happens when internal pressure keeps building until something gives way. At the same time, checking for leaks becomes crucial as temperatures rise because even small gaps can become major problems. Rapid gas decompression tests are especially relevant for folks working in oil fields and gas plants. These tests mimic those sudden pressure crashes that happen naturally in these environments, and if there's gas trapped inside the rubber components, it can cause blisters that ultimately lead to catastrophic failures nobody wants to deal with.

Industry Standards and Qualification Protocols for O-Ring Reliability

Meeting standards like ASTM D1414 for chemical compatibility, SAE AS5857 regarding aerospace compression set, and ISO 23936-2 on RGD resistance helps maintain product consistency across the board. Studies looking into why static seals fail show something pretty alarming actually. When exposed to heat over time, there's typically around a 40 percent drop in sealing power after just 500 hours at 150 degrees Celsius. That's way beyond what MIL-G-5514F considers acceptable. To make sure products can handle tough situations, manufacturers run both speeded-up aging tests and actual field trials that go well past 2000 hours. These extended stress tests give companies confidence their materials will perform reliably even when pushed to limits most wouldn't encounter in everyday operations.

Finite Element Analysis (FEA) for Predicting O-Ring Stress and Contact Pressure

Advanced FEA models simulate stress across O-ring cross-sections under combined thermal and mechanical loads. By evaluating contact pressure gradients and Von Mises stress peaks, engineers optimize:

- Groove geometry to minimize extrusion gaps at 10,000+ psi

- Material hardness (70-90 Shore A) for balanced elasticity and extrusion resistance

- Backup ring placement to reduce stress concentrations by 18-22%

Validated against physical testing, these simulations cut prototyping costs by 30% and identify risks such as edge nibbling or compression set creep before deployment.

FAQ

What are the main factors to consider when selecting O-ring materials for high-temperature applications?

The main factors include the maximum operating temperature, chemical resistance, and mechanical properties. Materials such as Viton, Silicone, and PTFE offer varying levels of heat and chemical resistance.

How do high-pressure applications affect O-ring performance?

High-pressure applications can lead to extrusion, deformation, and material degradation. Proper selection of materials and design, such as using backup rings, can help mitigate these issues.

Why is gland design important in high-pressure O-ring applications?

The gland design ensures that the O-ring remains in place under pressure, allowing for optimal sealing. Proper design prevents extrusion and mechanical failure.

What tests are conducted to ensure O-ring durability?

Tests include compression set, burst pressure, leakage evaluations, and rapid gas decompression to ensure materials perform well under extreme conditions.

Table of Contents

-

Selecting the Right O-Ring Material for High-Temperature and High-Pressure Applications

- Matching Elastomers to Extreme Conditions: Viton® (FKM), Nitrile, Silicone, and PTFE

- Temperature Limits and Chemical Resistance Trade-Offs of O-Ring Materials

- Degradation Risks Under High-Pressure Gases: Oxidation, Hardening, and Hydrogen-Induced Swelling

- Understanding Temperature Effects on O-Ring Seal Integrity

- Reversible vs. irreversible changes in elastomers at elevated temperatures

- Compression set and thermal expansion: Impact on long-term sealing performance

- Managing High-Pressure Challenges: Extrusion, Stress, and Mechanical Failure

- Optimizing Gland Design and Mechanical Support for Reliable O-Ring Seals

- Testing, Validation, and Durability Assessment of O-Rings Under Extreme Conditions

- FAQ