How O-Rings Work: Fundamentals of Sealing in Industrial Applications

O-rings achieve fluid-tight seals through controlled elastomer deformation. Their circular cross-section compresses into sealing grooves, generating radial forces that fill surface imperfections and prevent leakage. According to a 2023 polymer engineering study, properly specified o-rings deliver 95% leak prevention in industrial applications.

The Fundamental Sealing Mechanism of O-Rings in Industrial Environments

O-rings create sealing force when squeezed between two surfaces that fit together. As the rubber material gets compressed, it actually squishes into tiny spaces between those surfaces while keeping around 15 to 30 percent compression to work best. For things that don't move much, like connections between pipes, these seals can hold up against really high pressure sometimes reaching as much as 5,000 pounds per square inch. Getting the groove right where the o-ring sits makes a big difference too. Studies show that good groove design can make seals last almost 40 percent longer than when the grooves are too small. This matters a lot in industries where equipment needs to stay sealed for long periods without failure.

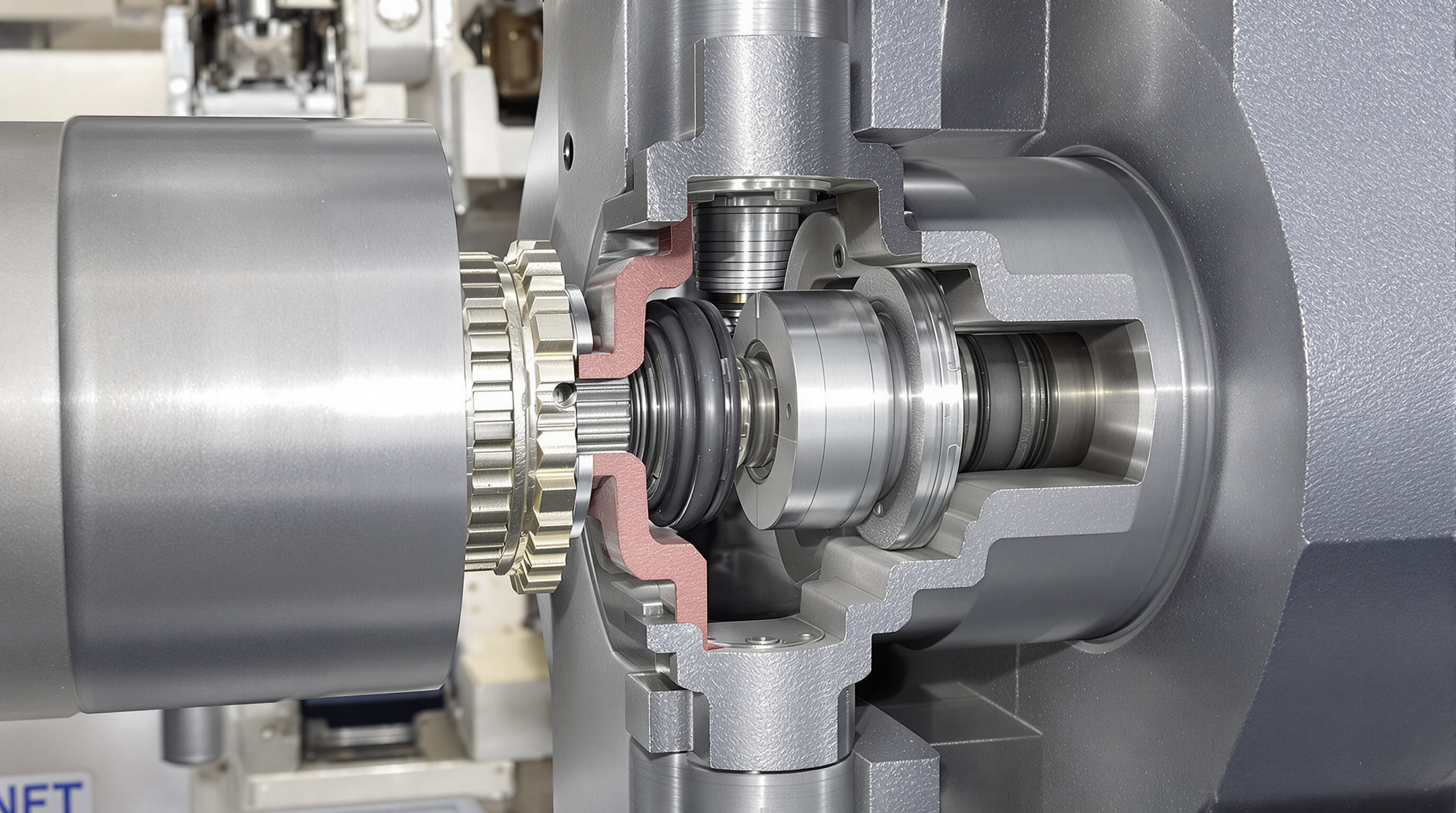

Static vs Dynamic Sealing: How O-Rings Adapt to Different Mechanical Stresses

- Static Seals rely on materials with low compression set (≤25% after 24 hours at 212°F) to maintain sealing force without movement

-

Dynamic Seals require abrasion-resistant compounds such as hydrogenated nitrile (HNBR), which can endure over 1 million cycles in hydraulic cylinders

In high-pressure oil and gas systems exceeding 10,000 psi, specialized urethane o-rings are used to limit extrusion in gap distances of ≤0.003", per 2023 API standards.

Key Performance Indicators for Effective O-Ring Sealing

| Parameter | Target Range | Measurement Standard |

|---|---|---|

| Compression Set | ≤20% after 168h @ 257°F | ASTM D395 |

| Tear Strength | ≥250 pli | ASTM D624 Die C |

| Temperature Range | -65°F to +446°F (FKM) | ISO 2230 |

Proper hardness selection (70–90 Shore A) reduces seal failures by 60% in chemical processing equipment, according to a 2023 material compatibility study.

Selecting the Right O-Ring Material Based on Chemical, Thermal, and Mechanical Demands

When picking materials, there are basically three main things to consider: how they react chemically, what temperatures they can handle, and their physical durability. Studies show that about two thirds of all seal problems actually come down to chemicals not getting along with each other. That makes sure the material can stand up to whatever it's exposed to absolutely essential for good performance. Temperature matters too when narrowing down options. Regular nitrile rubber works fine from around minus 30 degrees Fahrenheit up to about 250 degrees, but if we're talking about refineries where heat is extreme, then perfluoroelastomers or FFKM as they're called can take the heat right up to 600 degrees Fahrenheit. Looking at mechanical characteristics completes the picture. For instance, aerospace grade silicone shouldn't expand much more than 15% after sitting at 300 degrees for a thousand hours straight. Hydraulic seals need to be tough enough to hold at least 1,500 pounds per square inch before breaking. Putting all these aspects together cuts down how often parts need replacing by roughly three quarters in places where chemicals are really harsh.

Common O-Ring Materials and Their Industry-Specific Applications

Nitrile (NBR) O-Rings: Best for Oil and Fuel Resistance in Automotive Systems

Nitrile O-rings, also known as NBR, stand up pretty well against oils, fuels and those pesky hydraulic fluids we see everywhere. They work reliably within temperatures ranging roughly from minus 40 degrees Celsius all the way up to around 120 degrees Celsius (which translates to about -40 Fahrenheit to 250 Fahrenheit give or take). Because they last longer and don't cost too much, these rings are commonly used in places like car fuel injectors, transmission seals, and even brake systems where reliability matters most. What makes NBR special is how it keeps its shape and flexibility even after sitting in hydrocarbons for extended periods. This property helps cut down on engine leaks significantly when compared with regular old rubber materials that tend to break down faster under similar conditions.

FKM (Viton®): Superior Chemical and Temperature Resistance for Harsh Environments

FKM o-rings resist acids, solvents, and temperatures up to 200°C (392°F), making them essential in chemical processing, semiconductor manufacturing, and oil refineries. A 2023 industry study found that FKM seals reduce maintenance costs by 34% in chlorinated environments versus standard rubber compounds.

Silicone O-Rings: Flexible Performance in Extreme Cold and High-Heat Scenarios

Silicone o-rings remain flexible from -60°C to 230°C (-76°F to 446°F), serving critical roles in aerospace cryogenics and medical autoclaves. Their inert nature also supports food-grade applications such as beverage filling lines. However, due to lower tear strength, gland design must prevent extrusion under pressures above 1,500 psi.

PTFE and EPDM O-Rings: Niche Applications in Pharmaceutical and Water Treatment Sectors

PTFE o-rings provide near-universal chemical inertness, ideal for pharmaceutical CIP/SIP processes. EPDM’s ozone resistance (up to 10 ppm) makes it suitable for water treatment valves and HVAC systems. These materials meet FDA and NSF/ANSI 61 requirements, with EPDM lasting 3–5 times longer than nitrile in potable water applications.

Managing Pressure and Environmental Stress to Prevent O-Ring Failure

How Pressure Affects O-Ring Extrusion and Seal Integrity

When pressure gets too high, it causes what's known as extrusion in seals, basically when an O-ring gets pushed into those tiny spaces between parts that fit together. The danger really kicks in once we hit around 1,500 psi, particularly noticeable with softer stuff like nitrile rubber (NBR) or silicone materials. What happens then is pretty straightforward but problematic: the rubber starts to squish outwards instead of staying put, which messes up how well it can seal things off and leads to leaks down the line. From what many engineers have seen across different industries, equipment running past that pressure mark works better with tougher materials rated at least 90 on the Shore A scale or goes for composite designs that handle stress differently.

Pressure cycling exacerbates wear by promoting compression set–a permanent loss of elasticity that diminishes rebound capacity. In dynamic seals, repeated compression generates heat (up to 30°C above ambient), accelerating chemical degradation and reducing service life.

Design Strategies to Prevent O-Ring Failure Under High-Pressure Sealing

Four proven engineering strategies enhance o-ring reliability in demanding conditions:

Gland Geometry Optimization

Tighter diametrical clearances (≤0.005” for systems above 1,000 psi) minimize extrusion paths while ensuring proper squeeze (15–30% for static seals).Backup Ring Integration

PTFE or nylon backup rings support o-rings in ultra-high-pressure applications (>5,000 psi), blocking elastomer flow and distributing stress evenly.Material Hardness Selection

High-durometer materials such as polyurethane (95 Shore A) offer superior extrusion resistance compared to standard nitrile at equivalent pressures.System Pressure Monitoring

Integrating real-time sensors with automated relief valves keeps o-rings within rated pressure limits, mitigating fatigue.

Combining these approaches with preventive maintenance every 500 operating hours extends o-ring service life by 40–60%, according to industrial sealing reliability data.

Application-Specific O-Ring Selection Across Critical Industries

Oil and gas sector: Demanding conditions requiring high-temperature and pressure-resistant o-rings

The harsh realities of offshore drilling and refinery work put enormous stress on o-rings. These components face depths exceeding 10,000 feet underwater, temperatures that can hit around 350 degrees Fahrenheit, and pressure levels sometimes climbing past 15,000 pounds per square inch. According to research from ASM International in 2023, fluorocarbon or FKM materials maintain approximately 94% of their original tensile strength even after sitting for 1,000 hours in sour gas conditions. Meanwhile, perfluoroelastomers known as FFKMs play a critical role in preventing catastrophic failures during decompression events at those deep sea oil wellheads called Christmas trees. When choosing materials for such demanding applications, several factors come into play that need careful consideration based on specific operational requirements.

- Resistance to sulfide stress cracking in H₂S-rich wells

- Compression set below 15% following extended hydrocarbon exposure

Pharmaceutical and food processing: Hygienic o-ring materials meeting FDA and USP standards

Steam sterilization (15 PSI at 121°C) demands platinum-cured silicone o-rings that comply with USP <661> guidelines, limiting extractables to less than 0.5%. In Clean-in-Place (CIP) systems, EPDM exhibits 40% lower biofilm adhesion than nitrile when exposed to 4% sodium hydroxide solutions (Food Safety Magazine 2022). Certification compliance drives material decisions:

| Compliance Standard | Application Example | Key O-Ring Property |

|---|---|---|

| FDA 21 CFR §177.2600 | Dairy homogenizers | Zero milk fat absorption |

| USP Class VI | Vial capping stations | Non-pyrogenic surface |

Aerospace and defense: Precision o-rings for dynamic, high-reliability environments

The hydraulic actuators found on aircraft rely on fluorosilicone O-rings that have incredibly tight tolerances around 0.0003 inches or about 7.6 micrometers. These tiny rings are what keep things working when planes experience those massive 5,000 PSI pressure spikes during landings on carriers. For missile guidance systems, engineers turn to HNBR compounds because they can handle extreme temperature swings from as cold as minus 65 degrees Fahrenheit all the way up to 300 degrees Fahrenheit without compromising their ability to block electromagnetic interference. According to reports from NTSB in their 2022 Aerospace Materials Study, getting the right specifications for these O-rings makes a huge difference. Properly selected materials cut down on fluid system failures by almost three quarters in supersonic flight conditions, which is pretty impressive considering how demanding those environments are.

FAQ Section

What are the main types of o-ring seals?

The main types of o-ring seals are static seals and dynamic seals. Static seals are used where little movement occurs, while dynamic seals accommodate moving parts and require abrasion-resistant compounds.

Why is o-ring material selection important?

O-ring material selection is critical because it ensures compatibility with chemical, thermal, and mechanical conditions of the application. This reduces the risk of seal failure and extends service life.

How does pressure affect o-ring performance?

High pressure can cause extrusion, where the o-ring gets pushed into small gaps, leading to leaks. Proper material and design strategies are necessary to manage pressure effects on seal integrity.

Table of Contents

- How O-Rings Work: Fundamentals of Sealing in Industrial Applications

- Selecting the Right O-Ring Material Based on Chemical, Thermal, and Mechanical Demands

-

Common O-Ring Materials and Their Industry-Specific Applications

- Nitrile (NBR) O-Rings: Best for Oil and Fuel Resistance in Automotive Systems

- FKM (Viton®): Superior Chemical and Temperature Resistance for Harsh Environments

- Silicone O-Rings: Flexible Performance in Extreme Cold and High-Heat Scenarios

- PTFE and EPDM O-Rings: Niche Applications in Pharmaceutical and Water Treatment Sectors

- Managing Pressure and Environmental Stress to Prevent O-Ring Failure

- Application-Specific O-Ring Selection Across Critical Industries

- Oil and gas sector: Demanding conditions requiring high-temperature and pressure-resistant o-rings

- Pharmaceutical and food processing: Hygienic o-ring materials meeting FDA and USP standards

- Aerospace and defense: Precision o-rings for dynamic, high-reliability environments

- FAQ Section