What Makes a Rubber Bushing Suitable for High-Load Construction Applications?

Load-Bearing Mechanics: How Rubber Bushings Distribute Stress in Heavy Machinery

Rubber bushings work really well in construction gear because they spread out heavy point loads over a larger area instead of letting them concentrate on one spot. What makes these parts special is how they soak up shocks that would normally crack or break stiffer parts made of steel or other metals. Take an excavator bucket hitting a big rock or a bulldozer running into something unexpected on site. The rubber bushing gets compressed both ways at once radial compression mixed with twisting motion spreading all those forces out across its whole surface. Tests using computer modeling have found that these rubber parts cut down stress levels by more than half compared to traditional metal sleeves. Another benefit comes from the unique rubber qualities that help control annoying engine vibrations from diesel motors and hydraulic pumps. This stops those constant shaking patterns from building up and wearing out metal joints faster than normal. Good quality bushings keep everything lined up properly even when there's some wobble in the system, handling misalignment angles of around 5 degrees which matters a lot for dump trucks that need to move through rough ground conditions day after day.

Material Science Fundamentals: Durometer, Compression Set, and Resilience Metrics

Three material properties define high-load rubber bushing performance:

- Durometer (Shore A 60-90): Hardness determines load capacity without sacrificing flexibility. Mining equipment uses 80-90 Shore A for 50+ ton loads; vibration-sensitive applications favor softer compounds.

- Compression Set (<15% @100°C): Measures permanent deformation after sustained loading. Low compression set ensures consistent performance in crane outriggers after months of compression.

- Rebound Resilience (>60%): Indicates energy return efficiency. High resilience minimizes heat buildup in continuous compaction equipment like vibratory rollers.

HNBR, or Hydrogenated Nitrile Butadiene Rubber, is among those advanced materials that actually meet the ASTM D2000 requirements when it comes to resisting oils. These rubbers work well across a pretty wide temperature range too, staying reliable even when temps drop to minus 40 degrees Celsius or climb up to 150 degrees. Real world testing has shown something interesting about these materials they still hold about 90 percent of their original strength after sitting through 10,000 hours of rough conditions. And what's really impressive is how they handle heat over time. When subjected to thermal aging tests at 120 degrees Celsius, most samples only lose around 20 percent of their properties within 1,000 hours. That kind of durability makes them especially valuable equipment for things like asphalt paving machines and hot mix plants where extreme conditions are just part of daily operations.

Rubber Bushing Shock Absorption and Vibration Damping in Off-Highway Equipment

Heavy-duty construction equipment like excavators and loaders face relentless vibration from uneven terrain and dynamic loads. Rubber bushings mitigate these forces through viscoelastic energy dissipation-converting mechanical stress into heat. This prevents structural fatigue in booms, frames, and undercarriages while enhancing operator comfort.

Real-World Damping Challenges in Excavators, Loaders, and Articulated Trucks

When articulated dump trucks take corners, they're subjected to serious twisting forces that put enormous stress on their suspension components. This means the bushings need to handle high levels of shear resistance to keep things running smoothly. For excavators, the swing system gets hit with torsional vibrations every time it rotates through its cycle. Getting the damping right here is absolutely critical for protecting those expensive gearboxes from premature failure. Wheel loaders deal with another challenge altogether when loading buckets full of material. The sudden impact shocks can really take a toll on equipment, and how much the bushings deflect makes all the difference in how long various parts will last before needing replacement. According to recent findings from the Industrial Maintenance Report 2023, failing to isolate these vibrations properly can lead to accelerated wear rates in hydraulic lines and bearings by around 40%. That kind of degradation adds up fast over time and costs operators significant amounts in repairs and downtime.

Optimizing Dynamic Response: Preload, Deflection Range, and Frequency Isolation

When we talk about controlled preload, what we're really looking at is how bushings hold their stiffness when first compressed. Good engineering means setting those deflection limits just right so they can handle big impacts without hitting rock bottom, but also keeping things from getting squashed too much which makes them wear out faster through this thing called creep. For frequency isolation work, engineers focus on those tricky resonance points around 8 to 15 Hz commonly found in loader cabs these days. They accomplish this with these special laminates made from different rubber hardness levels. The secret sauce? Putting harder materials on the outside and softer stuff inside creates about 70% less vibration in key areas. This setup actually makes parts last longer since there's less direct metal touching metal at those pivot points where most wear happens anyway.

Long-Term Durability of Rubber Bushings Under Extreme Environmental and Mechanical Stress

Temperature, Ozone, and Fluid Resistance: Selecting Elastomers for Harsh Job Sites

The rubber bushings used in construction equipment have to deal with some pretty tough conditions out there. We're talking about temperatures that can hit over 60 degrees Celsius in deserts all the way down to below minus 40 in Arctic regions. This kind of extreme weather really speeds up the oxidation process, which makes those rubber parts get hard and start cracking. And it's not just heat or cold that's a problem either. Even small amounts of ozone in the air can damage these materials. Studies show that when ozone levels reach around 25 parts per million, certain rubber compounds begin developing surface cracks. When looking at hydraulic systems specifically, how well materials resist fluids matters a lot. Nitrile rubber holds up pretty good when submerged in oil, swelling less than 10%. Meanwhile, EPDM rubber works better against glycol based fluids. Choosing the right material for any given application comes down to understanding three main factors:

- Durometer (70-90 Shore A) balances flexibility and load support

- Compression set (<20% at 100°C) predicts shape retention

- Tensile strength (>15 MPa) ensures tear resistance

Fatigue Life Prediction: Accelerated Testing and Field Validation Protocols

To check how long bushings will last, engineers need to speed up time dramatically, squeezing decades worth of wear into just a few weeks of testing. The accelerated testing process puts prototypes through over 10,000 load cycles at 150 percent beyond normal operating conditions while keeping an eye on how cracks form and spread. After this lab work comes field validation where actual performance gets compared against those controlled environment results across various mining operations and quarry settings. This two step method helps spot common failure spots such as areas where stress builds up at material joints, allowing design tweaks that can boost service life by around 30 percent when geometry is optimized properly. For thermal testing, samples sit at 125 degrees Celsius for half a thousand hours to mimic what happens over many years. These tests confirm whether bushings will hold up during their expected ten year lifespan in critical components like excavator pivots and loader arm connections.

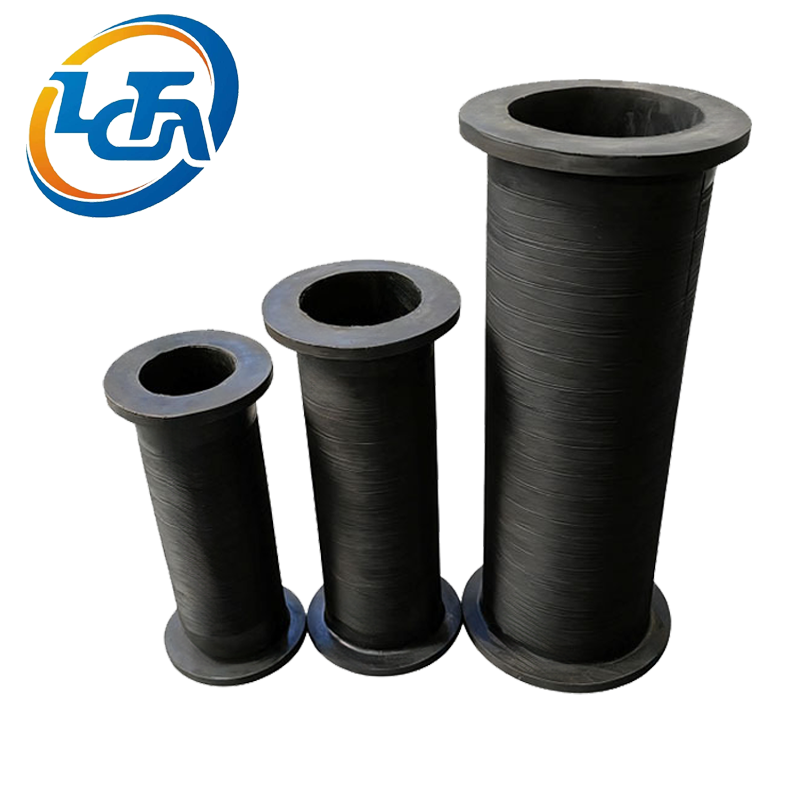

Custom Rubber Bushing Manufacturing for Precision Fit and Application-Specific Performance

Construction gear needs rubber bushings built for specific job conditions because generic parts just don't hold up when things get rough out there. That's where custom made bushings come in handy. They're designed with careful attention to how they'll be used, what materials work best, and tested thoroughly before shipping. When engineers look at the forces acting on a machine, they consider all sorts of stresses including twisting motions, repeated pressure changes, and sudden impacts. These factors help decide the shape of the bushing, how thick the walls need to be, and where it should attach to other components. For materials, manufacturers pick special rubbers that can handle extreme temperatures ranging from -40 degrees Fahrenheit right up to 250 degrees. These materials also resist damage from hydraulic fluids and ozone exposure. Many times, they go with harder rubber compounds rated between 70 and 90 on the Shore A scale for parts that carry heavy loads. The actual manufacturing process matters too. Techniques such as injection molding or compression casting keep dimensions accurate within about 0.005 inches, which prevents problems caused by parts not lining up properly. After making them, companies run tests that simulate thousands of hours of operation to check if the bushings will bend correctly and dampen vibrations effectively over time. Field reports show that this customized method cuts down on maintenance needs by around 40 percent compared to standard bushings. Operators notice longer lasting performance especially in important areas like the boom sections of excavators and the linkage systems on loaders.

Table of Contents

- What Makes a Rubber Bushing Suitable for High-Load Construction Applications?

- Rubber Bushing Shock Absorption and Vibration Damping in Off-Highway Equipment

- Long-Term Durability of Rubber Bushings Under Extreme Environmental and Mechanical Stress

- Custom Rubber Bushing Manufacturing for Precision Fit and Application-Specific Performance