The Critical Role of Silicone Rings in Beverage Equipment Sealing

Why Reliable Sealing Matters in Beverage Dispensing Systems

Preventing leaks matters a lot for beverage dispensing systems because when seals fail, it leads to wasted product, possible contamination issues, and all sorts of downtime problems. Just one bad seal at a busy soda fountain area can cause sticky messes to build up over time, create conditions for bacteria to grow, or let syrup leak out everywhere. This kind of problem costs businesses around 15 percent each year on maintenance work. Silicone rings help solve these issues since they form really tight barriers against the ups and downs of pressure changes and temperature fluctuations that happen regularly in those carbonated drink dispensers we see everywhere.

How Silicone O-Rings Ensure Leak-Free, High-Performance Operation

The special way silicone is built gives O-rings their amazing ability to stay flexible even when temperatures drop below freezing or climb well above boiling point. Equipment needs this kind of flexibility whether it's dealing with frozen drinks or steaming hot coffee. Traditional rubber just doesn't hold up like silicone does against compression set issues which can really mess with the seal after repeated use. Over time, this means silicone lasts much longer than regular nitrile seals many operators are used to working with. Some tests show replacements happen about 40 percent less often with silicone parts. Plus, there are specific silicone formulas approved by the FDA that won't let any chemicals sneak into the drinks they're meant to protect, giving businesses peace of mind about safety standards.

Case Study: Preventing Drips in Commercial Soda Fountain Machines

A national quick-service restaurant chain reduced post-mix syrup waste by 32% after retrofitting 2,500 dispensers with food-grade silicone rings. The seals' 94% resistance to carbonation-induced swelling (vs. 76% for EPDM rubber) minimized drips at valve junctions. Post-installation inspections showed a 19-month average service life–double the performance of previous sealing materials.

Compliance with FDA and Sanitary Standards for Food-Grade Silicone Rings

Meeting FDA Requirements (21 CFR 177.2600) for Food Contact Surfaces

Silicone rings used in food applications need to meet FDA regulations under 21 CFR 177.2600. Basically, this means the material has to stay stable and safe even after long periods touching food products. The rules are there to keep out harmful stuff like phthalates, heavy metals, and any other chemicals that might seep into drinks over time. Recent testing from the FDA in 2023 showed something pretty impressive though. When comparing certified silicone rings against those without proper certification, the good ones cut down contamination risks by nearly 99.7%. That's why most commercial soda machines and juice bottling lines rely on these approved materials. They just make sense for keeping beverages clean and customers healthy.

Adhering to USDA and 3A Sanitary Standards in Dairy and Beverage Processing

USDA Grade A dairy standards along with the 3A Sanitary Certification demand that silicone seals hold up against multiple rounds of steam sterilization at temperatures reaching around 300 degrees Fahrenheit. They also need to resist harsh Clean-In-Place chemicals such as peracetic acid during cleaning cycles. These requirements are not just about meeting regulations but actually preventing places where bacteria might hide. For equipment like dairy homogenizers and those big fermentation tanks used in craft breweries, even tiny surface flaws become major problems. A small crack or uneven spot can be enough to cause product contamination issues down the line, leading to costly recalls that hurt both reputation and bottom lines across the food production industry.

Ensuring Hygiene, Safety, and Regulatory Consistency Across Regions

Global manufacturers navigate regional variances–for example, the EU’s Framework Regulation (EC) 1935/2004 emphasizes migration limits, while Asia-Pacific markets prioritize NSF/ISO 21469 lubricant compatibility. Leading producers adopt dual-certification strategies, combining FDA and ISO 22000 protocols, to ensure seals meet hygiene benchmarks across 85% of international markets.

Material Advantages: Temperature and Chemical Resistance of Silicone Rubber

Withstanding Thermal Extremes in Pasteurization and Cold Chain Equipment

Silicone rubber keeps seals working properly even when temperatures swing from super cold at minus 55 degrees Celsius all the way up to scorching hot 300 degrees Celsius (that's roughly -67 Fahrenheit to 572 Fahrenheit). This makes it ideal for beverage equipment that goes through pasteurization at around 85 to 95 degrees Celsius and also handles cold storage conditions down to minus 18 degrees. Regular rubbers start breaking down once they hit about 120 degrees Celsius, but tests from Reiss Manufacturing back in 2023 showed that silicone stays flexible at around 90% of its original level even after sitting at 200 degrees Celsius for 1,000 straight hours. The real world benefit? No more failed seals during those intense ultra high temperature milk processing runs where other materials just can't handle the constant heating and cooling cycles without cracking apart.

Chemical Resistance to Cleaning Agents and Beverage Residues

Silicone’s polymer structure resists degradation from alkaline cleaners (pH 13), acidic beverages (pH 2.5–4), and oxidizing agents such as 5% hydrogen peroxide. Testing found silicone seals lost only 7% tensile strength after 500 hours in caustic soda, outperforming EPDM seals, which experienced a 32% loss.

Case Study: Silicone Gaskets in Hot Fill Juice Bottling Lines

A 2023 retrofit of 17 bottling lines replaced fluorocarbon seals with FDA-grade silicone gaskets, yielding:

| Metric | Before Silicone | After Silicone | Improvement |

|---|---|---|---|

| Seal replacement rate | 38/month | 6/month | 84%– |

| Downtime | 22 hours/month | 3 hours/month | 86%– |

| Product loss | $8,200/month | $900/month | 89%– |

Research from Raw Source attributes this to silicone’s combination of thermal stability and chemical inertness, which eliminated swelling from acidic fruit compounds.

Biocompatibility and Food-Safe Properties of Silicone O-Rings

Non-Toxic, Odorless Performance in Direct Food and Beverage Contact

Silicone O-rings help keep food safe because they don't react chemically with what they come into contact with, so there's no risk of affecting taste or purity. What makes them stand out from regular rubber is their stable molecular makeup which stops things like plasticizers or heavy metals from seeping out. Recent research published in 2024 by the International Journal of Biological Macromolecules shows these silicone rings meet all the safety standards set by ISO 10993 for biological testing. Another big plus? They stay completely odorless even after sitting in super acidic drinks (think anything below pH 3) or fatty dairy stuff. This means brewers and soda fountain operators don't have to worry about flavors mixing together accidentally in their equipment.

Scientific Safety vs. Consumer Perception: Addressing Industry Mistrust

Even though there's over seven decades worth of safety records from the FDA, many people remain wary about using synthetic stuff in areas where food touches surfaces. Independent tests have found that silicone O rings only let out less than one hundredth of a percent in extractables when exposed to heat around 180 degrees Fahrenheit, which actually meets those strict European standards from regulation 10/2011. Still, according to recent industry polls, nearly a third of folks running beverage operations prefer going old school with natural options such as cork or latex instead. To close this knowledge gap between science and perception, manufacturers need to start being more transparent about their NSF ANSI 51 certifications and provide detailed contaminant reports for each production batch right at the point when buying new equipment.

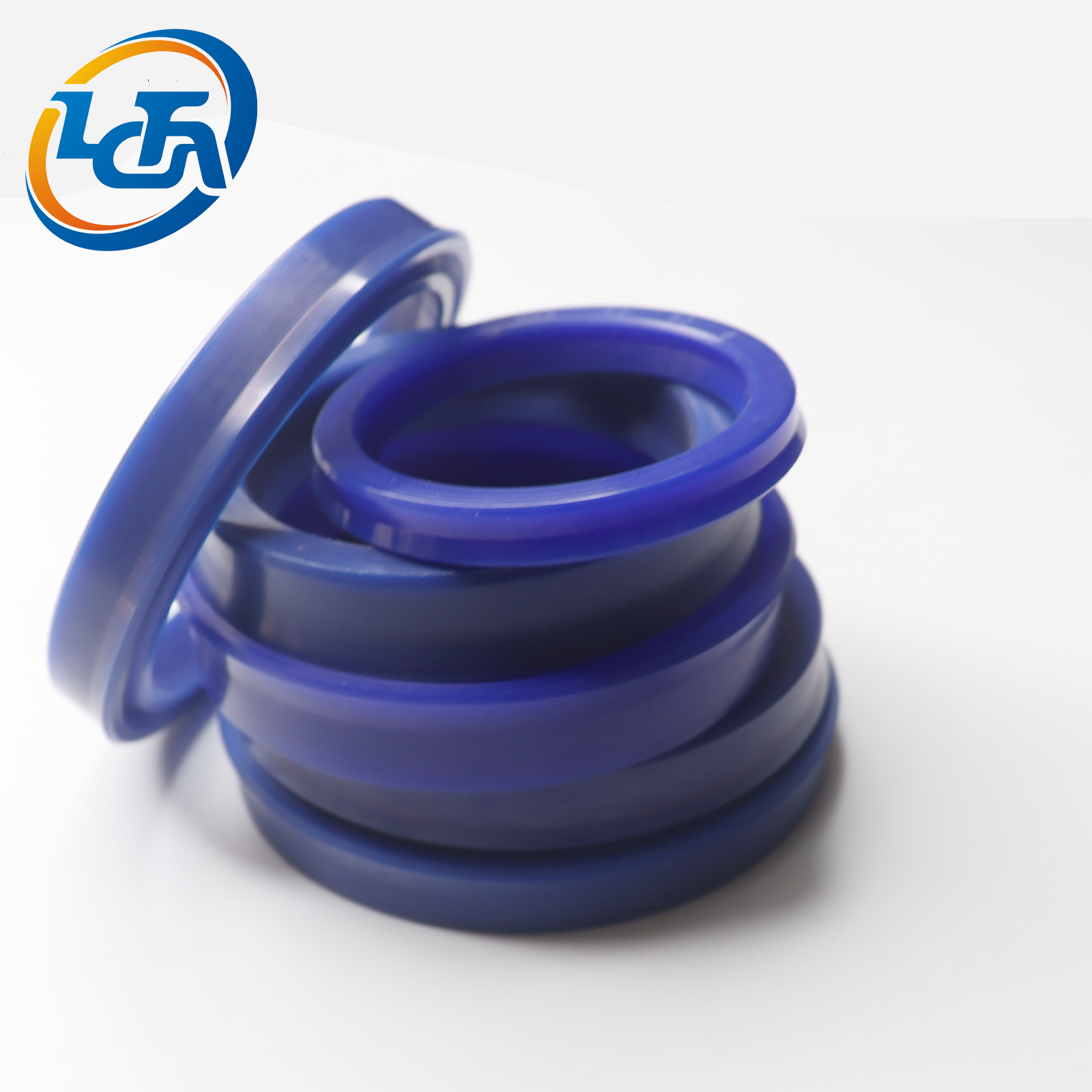

Design, Customization, and Long-Term Durability of Silicone Seals

Custom Molding for Application-Specific Beverage Equipment Needs

When it comes to getting the most out of them, silicone rings really shine when they're tailored to fit particular beverage equipment needs. Most manufacturers rely on specialized molding methods to produce seals that actually work with the strange shapes of ports, handle different pressure levels, and survive the temperature swings common in soda dispensers, beer taps, and juice bottling operations. According to a recent industry report from 2025 looking at sealing systems across various sectors, machines equipped with these custom-made silicone rings saw about 62 percent fewer leaks than those stuck with off-the-shelf generic seals. The difference matters a lot in places where downtime costs money, such as busy coffee shops running their espresso machines all day long or large scale dairy processing facilities where even small improvements can translate into significant savings over time.

Precision Engineering and OEM Collaboration for Optimal Fit

Getting rid of leaks isn't something that happens by accident. It takes real teamwork between those who make seals and the folks designing beverage equipment when they're still working on prototypes. These days, engineers can actually use computer models and printed parts to check how much pressure silicone rings need to hold against all sorts of shapes like those tricky curved dispensers and weird angle connections. Take dairy processing plants for instance. Many top facilities have started using these special two-part silicone seals lately. The inside part stays firm so everything holds together properly, while the outside is softer to handle all that constant valve movement without breaking down over time.

Extending Service Life Through Proper Installation and Predictive Maintenance

Silicone rings that are properly installed tend to last around three to five years in commercial drink machines, especially when paired with alignment guides and proper food safe lubrication. Maintenance crews who track things like compression changes and oxidation on their own schedule find they replace seals unexpectedly about 40 percent less often. Looking at actual milkshake machines across different locations shows something interesting too. When operators rotate those seals roughly every 18 months instead of waiting for problems, it stops syrup from forming crystals right where the seals meet. That crystal buildup is actually one of the biggest headaches for these machines in places where sugary drinks are constantly running through them.

Frequently Asked Questions

What makes silicone rings ideal for beverage equipment sealing?

Silicone rings are ideal because of their ability to stay flexible under extreme temperatures, resist degradation from chemicals and cleaning agents, and prevent leaks in beverage dispensing systems.

How do silicone rings compare to traditional rubber seals?

Silicone rings offer superior flexibility and longevity compared to traditional rubber, lasting longer and requiring fewer replacements due to their resistance to compression set issues.

Are silicone rings safe for food and beverage contact?

Yes, silicone rings meet FDA requirements for food contact surfaces and adhere to USDA and 3A sanitary standards, ensuring they are safe and non-toxic for use in food and beverage applications.

Can silicone seals be customized for specific equipment needs?

Yes, silicone seals can be custom molded to fit specific equipment needs, reducing leakage and improving overall performance in beverage processing environments.

What is the shelf life of silicone rings in beverage machinery?

Properly installed silicone rings can last between three to five years in commercial beverage machines, with fewer unexpected replacements required when predictive maintenance practices are employed.

Table of Contents

- The Critical Role of Silicone Rings in Beverage Equipment Sealing

- Compliance with FDA and Sanitary Standards for Food-Grade Silicone Rings

- Material Advantages: Temperature and Chemical Resistance of Silicone Rubber

- Biocompatibility and Food-Safe Properties of Silicone O-Rings

- Design, Customization, and Long-Term Durability of Silicone Seals